Industry 4.0 Barometer – 2023 Edition

Published May 15, 2024

- Automotive & Industry

- Industry 4.0 & IoT

For the eighth consecutive year, Wavestone joined forces with France Industrie and BPI France Le Hub to assess manufacturing progress throughout France from the perspective of maturity in technologies and organizations.

All eyes on AI, the new performance driver

In an era when digitized manufacturing is now a given, companies are focusing funds and efforts on next-generation technologies including Artificial Intelligence (AI) and advanced data use cases.

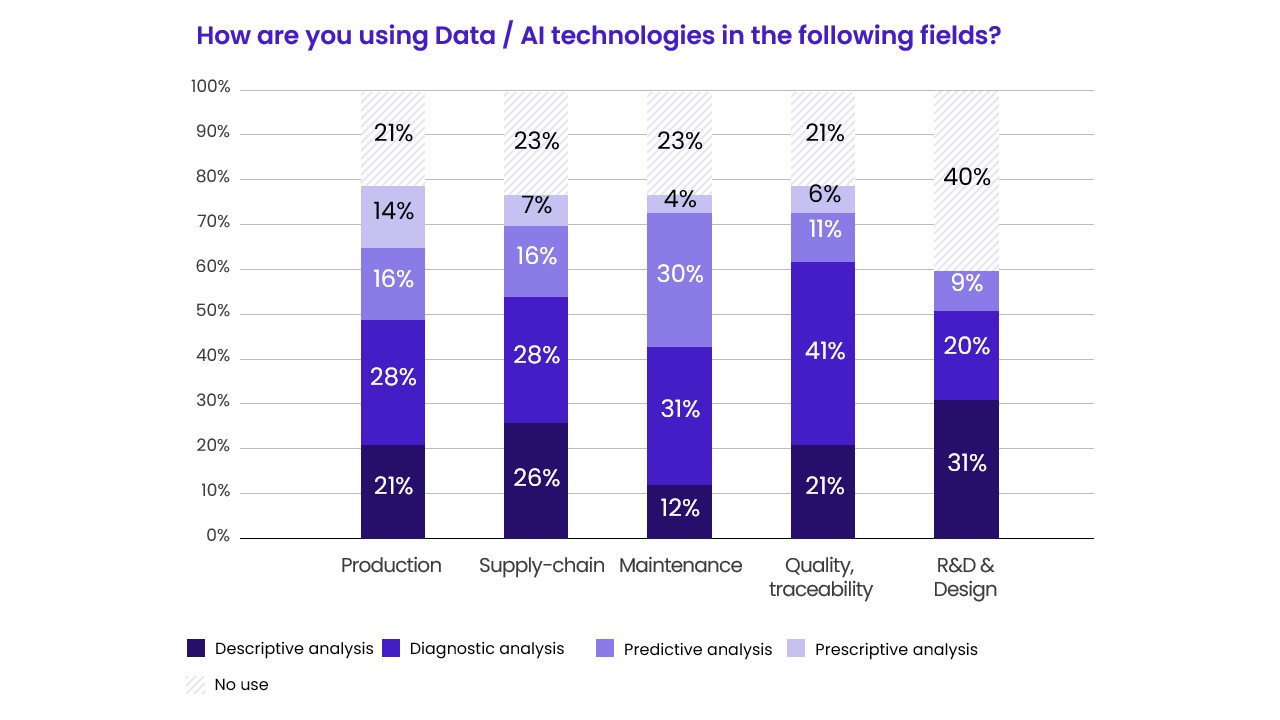

Data/AI technologies made their largest inroads in production (14%) and logistics (7%) networks, underscoring the need for performance. First, they perform repetitive tasks producing concrete results to learn, test and validate models. Only then can they be applied to more complex use cases.

Initiatives centered on quality and connectivity prove pivotal to the development of such technologies.

Phased solutions are required since manufacturers experience different levels of maturity. Regardless, the first step involves collecting data to conduct initial monitoring. Step number two shifts the focus to more complex models, factoring in predictive analytics and preventive measures.

Bolstering prevention in cybersecurity

New use cases open up new gateways for production networks, and subsequent cyber attacks. Cybersecurity is now either fully or close to top of mind: 97% of respondents reported that cybersecurity criteria are recognized in their 4.0 initiatives.

Manufacturers are mindful of such cyber attacks, with 82% of respondents establishing action plans to ensure business continuity and recovery. Phases then occur to test human and technology capabilities as well as further raise awareness among teams.

For companies at large, discipline falls short of what is needed to combat phishing and uphold cybersecurity best practice. Despite that trend, managers consider that the issue lies with cybersecurity; not them. In a parallel universe, what of a site manager neglecting responsibility for workers who not once wore a helmet, gloves or harness? In short, same difference!

Transitioning from reality check to real-life action in sustainability

At the same time, the key, now must-have concept behind responsible transformation continues trending, and has cemented its position at the top of the manufacturer priority list.

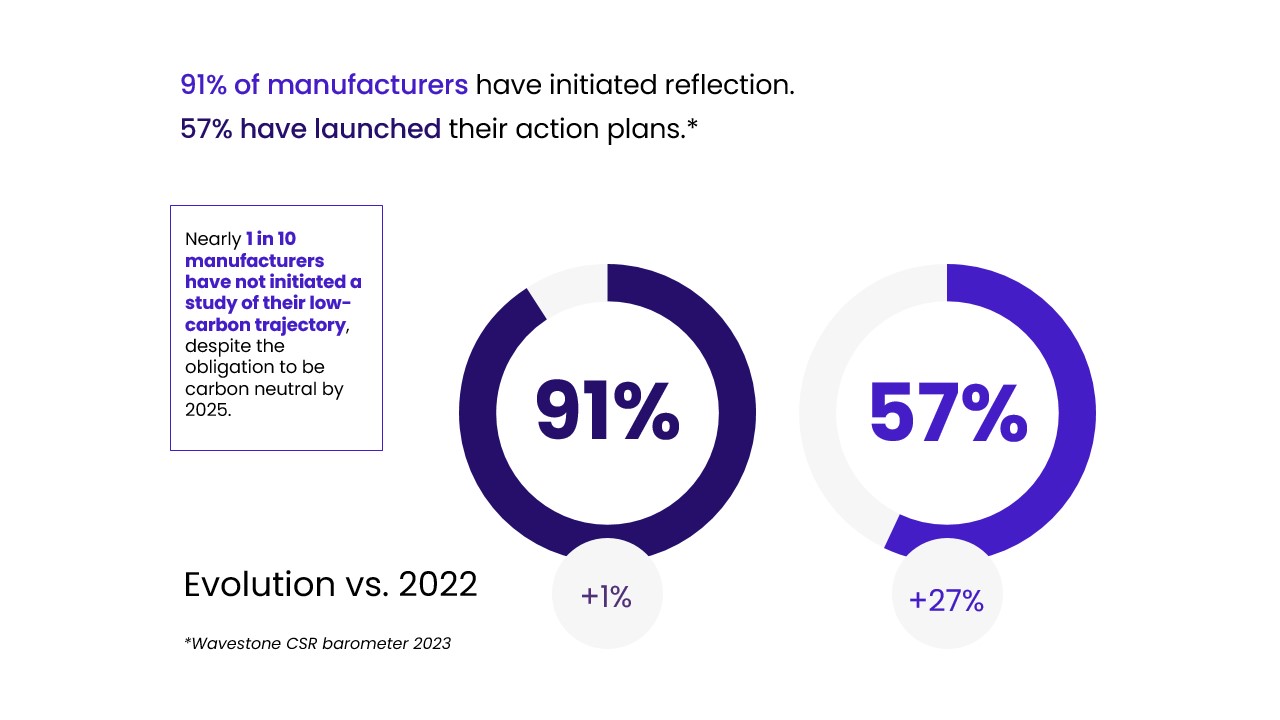

When it comes to the climate emergency, this reality check triggered decarbonization initiatives, leading 57% of manufacturers to kick-start action plans. Manufacturers have shifted up a gear, equipped with the resources to measure and control carbon emissions. Did you know 76% of manufacturers currently or will soon deploy a measurement tool?

To date, most decarbonization efforts are influenced by financial or regulatory factors.

To become carbon-neutral by 2050, some segments within industry are left constrained by the laws of chemistry and physics. That said, in the field of research, which is particularly powered by deep tech and disruptive innovation, ways exist to help us break through every single obstacle. After all, today’s impossible is tomorrow and after tomorrow’s reality.

Authors

For their contribution, thanks to : Lucie Varlet, Victoire Bénard-Ducy, Célestine Lorphelin, Matthieu Lahargoue, Corentin Thibert, Nicolas Fourquet, Julien Potrel, Arnaud Teyssie, Pierre Baranger, Antoine De Pouilly, Yann Bougaux, Hortense Phan, Pierre-Yves Audoy et Benoit Bouffard.